Capping Machines

To get detailed information about the products

You can contact us.

Semi-Automatic Capping Machine

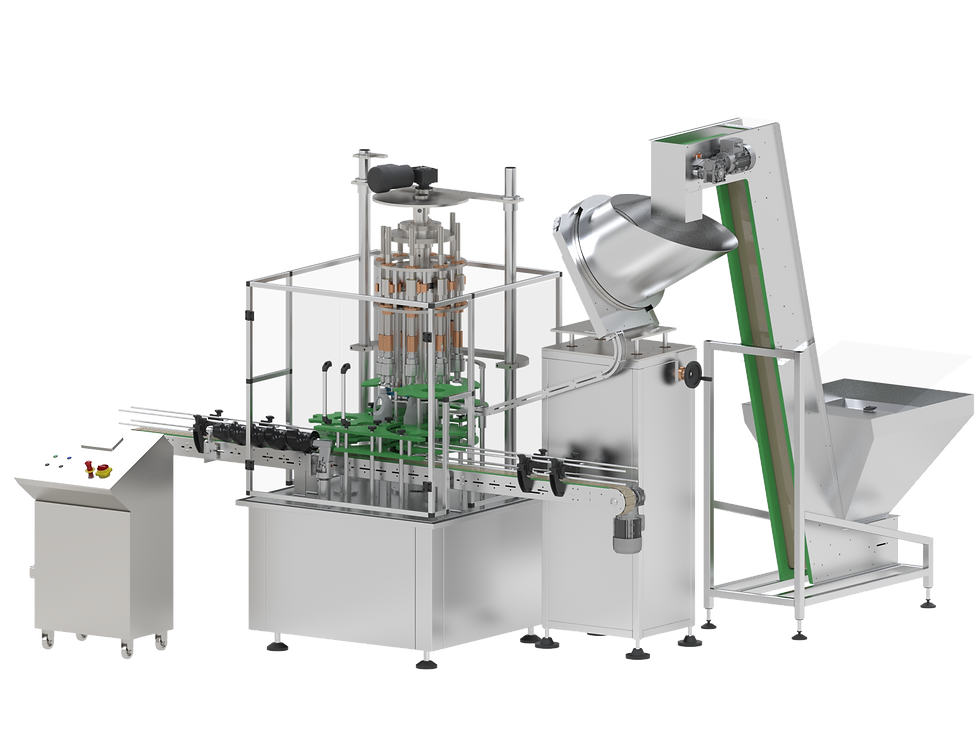

Modular Capping Machine

Rotary Capping Machine

Pharmaceutical Capping Machine

Models

Semi-Automatic Servo Shutdown

Modular Shutdown

Rotary Shutdown

Capacity

50-200BPM

Cover Type

Plastering

don't knock

screwed

Covered Products

We offer capping solutions for the filling processes of honey, ketchup, mayonnaise, syrup, serum, disinfectant, cologne, perfume and all liquid products.

What is automatic capping machine?

These are the machines that automatically close the lid after the filling process of plastic bottles, jars and similar products.

What are the prices of capping machines?

Please contact us for detailed product and price information.

What are the types of capping machines?

Customizations are made on the lid closing machines according to the lid types. Pet bottle closure, hdpe cap closure, jar closure, spray cap closure, pump cap closure, trigger pump cap closure, valve cap closure, aluminum spinning cap closure, servo cap closure, magnetic torque cap closure, crimp-on cap closure, perfume cap It can be diversified according to each sector and product, such as closure, screw cap closure, shampoo cap closure. Elektromag offers many solutions for capping machines.