Filling Machines

For detailed information about the products

You can contact us.

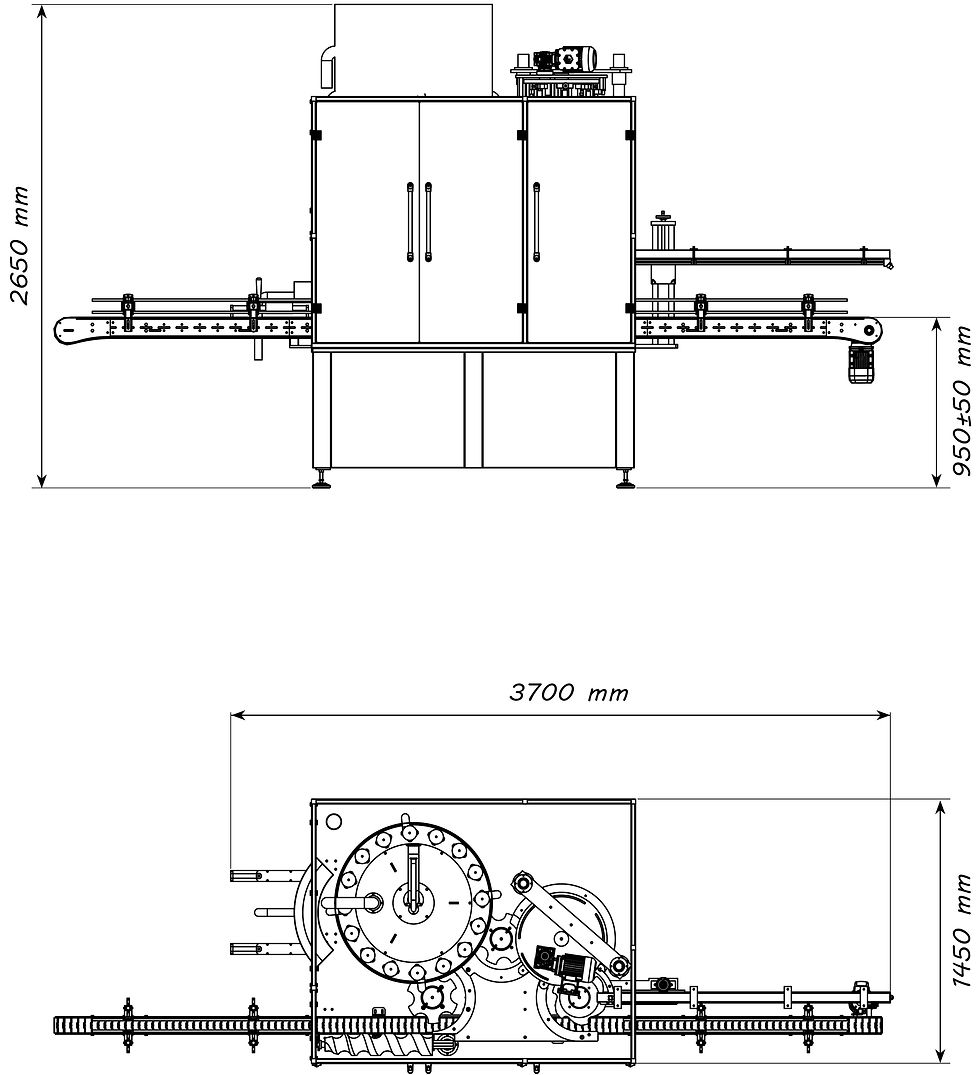

Linear Filling Machine

Load Cell Filling Machine

Rotary Filling Machine

Honey Filling Machine

Liquid Pharmaceutical Filling Machine

Models

Linear Filling

Rotary Filling

Load-Cell Filling

Capacity

600m/h

Number of Filling Nozzles

6-16-24

Filling Weight

It can be adjusted according to the desired weight.

Refillable Products

We offer solutions for the filling processes of shampoo, honey, ketchup, mayonnaise, liquid soap, disinfectant, cologne, perfume and all liquid products.

What is automatic liquid filling machine?

An Automatic Liquid Filling Machine works with the whole production line automated.

What is bottle filling machine?

Machines used for filling liquids into bottles are called bottle filling machines. Bottle filling machines are widely used in food, medicine, cosmetics, chemistry, etc. It is used in packaging processes in various industries.

How does the liquid filling machine work?

The liquid filling machine works when the pressure is high. This can be classified as liquid pressure filling, that is, when the pressure amount of the liquid tank is equal to the amount of air contained in the bottle, the liquid flows into the bottle according to its own weight.

What are the types of liquid filling machines?

For which products are liquid filling machines used, filling processes are carried out for all acid-free and fluid liquid substances. If we give an example of these products;

Shampoo Filling Machine

Shampoo filling machine, detergent filling machine, honey filling and sealing machine, medicine filling and sealing machine, mayonnaise filling and capping machine, sauce filling and sealing machine, liquid soap filling and sealing machine, perfume filling machine, cologne filling machine, bottle filling machine can be diversified according to the needs of each sector, such as disinfectant filling machine. As Elektromag, we offer solutions for gasless liquid filling production. Please contact us for prices of liquid filling machines.

Detergent Filling Machine

Detergent filling machines are filling machines that fill the liquid products. Many products can be filled with liquid detergent filling machine. It is also called liquid soap filling machine, it is used for liquid soap filling, bleach filling process, glass cleaner filling and similar products.

Cologne Filling Machine

The cologne filling machine is one of the liquid filling machines and fills the desired bottle form in mass production. It is also used as a disinfectant filling machine.

Oil Filling Machine

Olive oil filling machine is also called olive oil bottling machine, tin oil filling machine. It has a load-cell feature, and there are some with different features,

Ayran Filling Machine

Fully automatic ayran filling machine performs ayran filling into the bottle.

Liquid Soap Filling Machine

Liquid soap filling machine is an automatic servo motor machine. It can fill the bottles with the desired weight by vacuuming the product to be filled from the tank on the product. You can contact us for liquid soap filling machine prices and technical details.

Bleach Filling Machine

With the bleach filling machine, you can fill products such as detergent and liquid soap. An automatic 8-line linear filling machine was used for bleach filling, the surfaces that the product comes into contact with are PVC material and the problem of bleaching the surfaces has been solved. You can contact us for bleach filling machine prices and technical details.

Ketchup Filling Machine and Sauce Filling Machine

With the bleach filling machine, you can fill products such as detergent and liquid soap. An automatic 8-line linear filling machine was used for bleach filling, the surfaces that the product comes into contact with are PVC material and the problem of bleaching the surfaces has been solved. You can contact us for bleach filling machine prices and technical details.